1. Overview of jzcb-t bus duct system

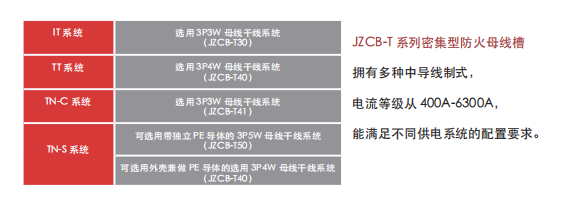

Jzcb-t series intensive bus duct, through years of research and accumulation, continuous improvement and verification, is a new generation of upgraded products carefully created for users.

The product integrates a variety of advanced technologies, and has won more than 10 national patents at one stroke. It has been recognized as a product adopting international standards by China National Standardization Management Committee and Guangdong Provincial Bureau of quality and technical supervision, and has been awarded the honorary title of high-tech products in Guangdong Province. Its technical indicators have reached the international leading level. It is a low-voltage power transmission and distribution center in the fields of modern airports, stations, factories, hotels, shopping malls, hospitals, office buildings, residential buildings and so on Distribution system is the preferred product for power transmission.

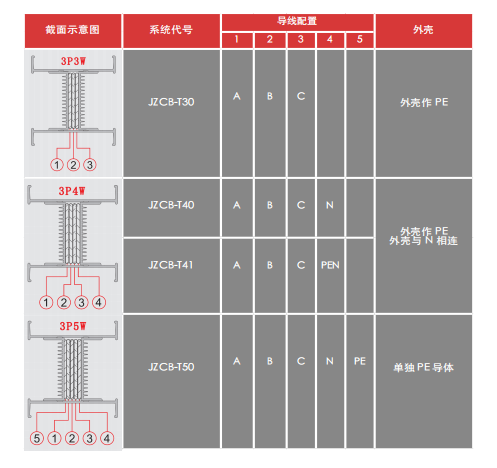

2. Wire configuration

3. Product mix

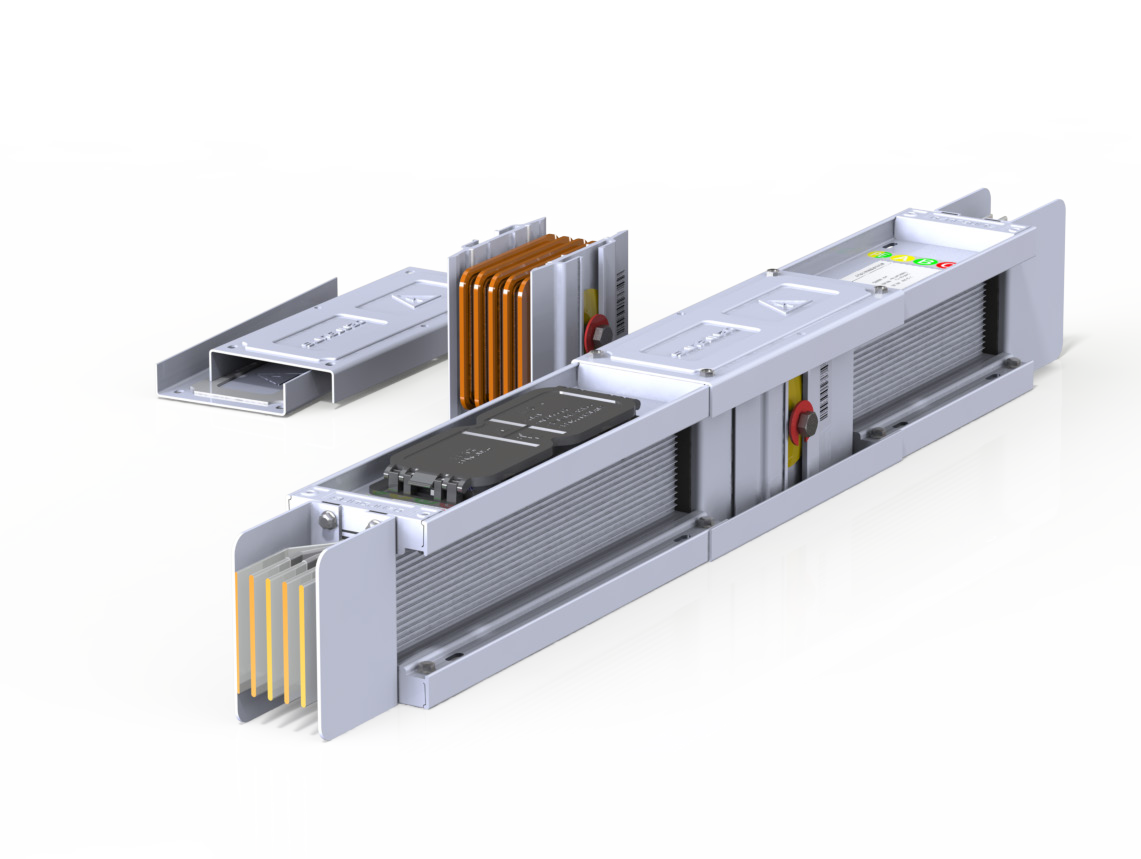

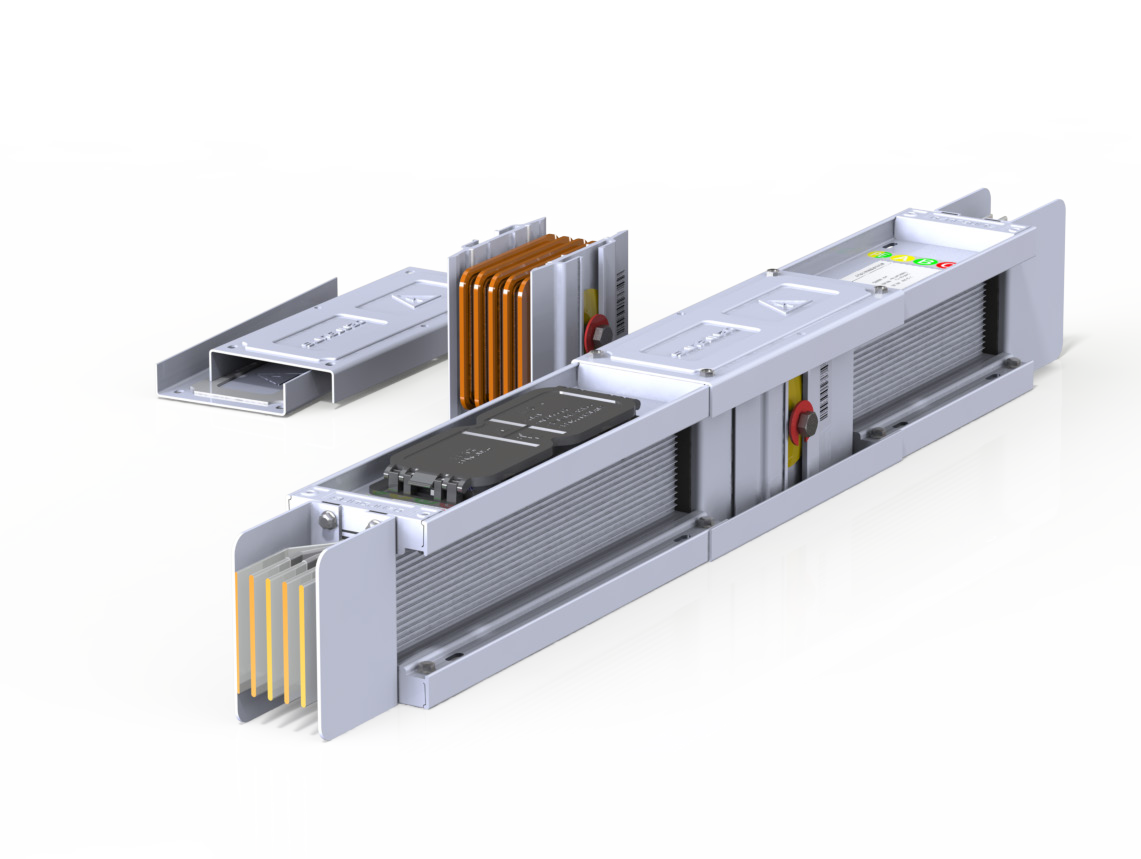

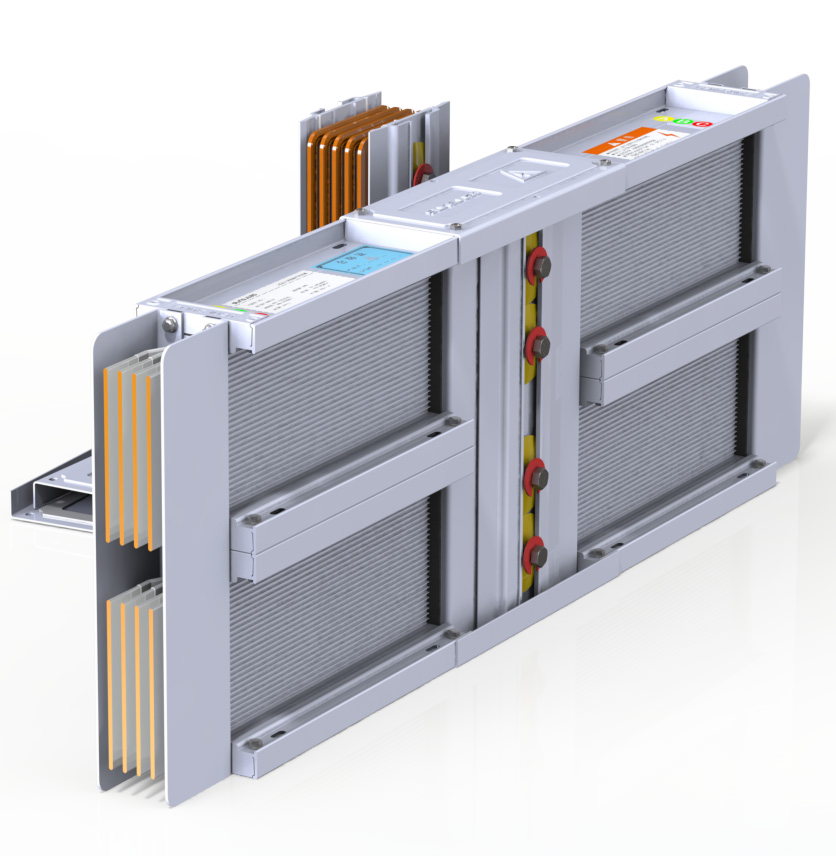

3.1 Compact "sandwich" structure

Jzcb-t series enclosed dense bus duct, whose conductor, insulating layer and shell are closely bonded together, is in a "sandwich" structure, with small volume, fast heat dissipation, low impedance, low temperature rise, high mechanical strength and good dynamic and thermal stability.

3.2 High degree of protection

The product is fully enclosed, and the joints are sealed with flame-retardant silicone strips, with a protection grade of up to 1p66.

3.3 Perfect connection unit

Jzcb-t connector unit adopts double copper transition connection, which fully ensures the overcurrent capacity of the system.

The shell is made of aluminum magnesium alloy, which fully ensures the reliability of system grounding. The insulating diaphragm is made of high-quality electrical insulating material BMC, which fully ensures the electrical safety of the system.

The fastener adopts double headed torque bolt. During installation, it only needs an ordinary wrench to tighten it until the bolt head close to the outside automatically breaks, so as to achieve the best effect of joint torque. The clamping groove of the shell on both sides of the connector is equipped with high-pressure balanced dished gasket. The pressure generated during bolt locking will be evenly transmitted to the connecting copper plate through the special dished gasket, so as to ensure the balanced stress on the contact surface between the connecting copper plate and the bus duct conductor, Achieve safe and reliable electrical connection.

The connector adopts the anti rotation design as a whole, and the silicone pad is sandwiched in the middle, which can be adjusted to the accurate docking distance with the bus duct at will, so as to truly achieve the effect of rapid connection. Waterproof rubber strips are set between all parts of the connector to ensure that the connection unit has the same protection level as the bus duct body.

The design of butt joint connector can effectively compensate the linear expansion and contraction caused by thermal expansion and cold contraction of the system. Without affecting the mechanical strength and electrical performance, each connector in the system can provide 6mm expansion compensation, so that jzcb-t system does not need to install special expansion unit in practical application.

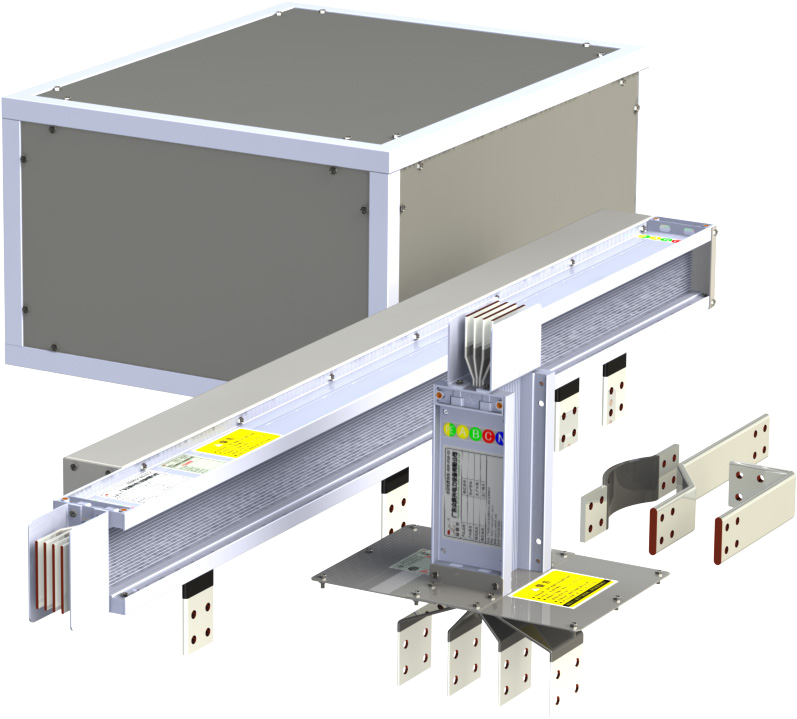

3.4 Initial incoming unit

Jzcb-t system is specially equipped with the starting incoming line unit connected with other equipment. It can be connected with generators, transformers, distribution boxes, distribution cabinets, cables and other equipment of different specifications and models. Soft connection transition can be selected when it is connected with generator, transformer and other equipment with large jitter, and hard connection transition can be selected when it is connected with distribution box, distribution cabinet and other equipment with small or no jitter.

In order to prevent the safety performance of the system from being affected by too long connecting conductors or too many turns, we can customize the starting end incoming line unit according to the size of the power feeding (receiving) equipment and the position of the terminal. To ensure the safety and beauty of the system.

In order to avoid the exposure of connecting conductors, we also configure the cabinet top incoming box to improve the safety performance and protection level of the system.

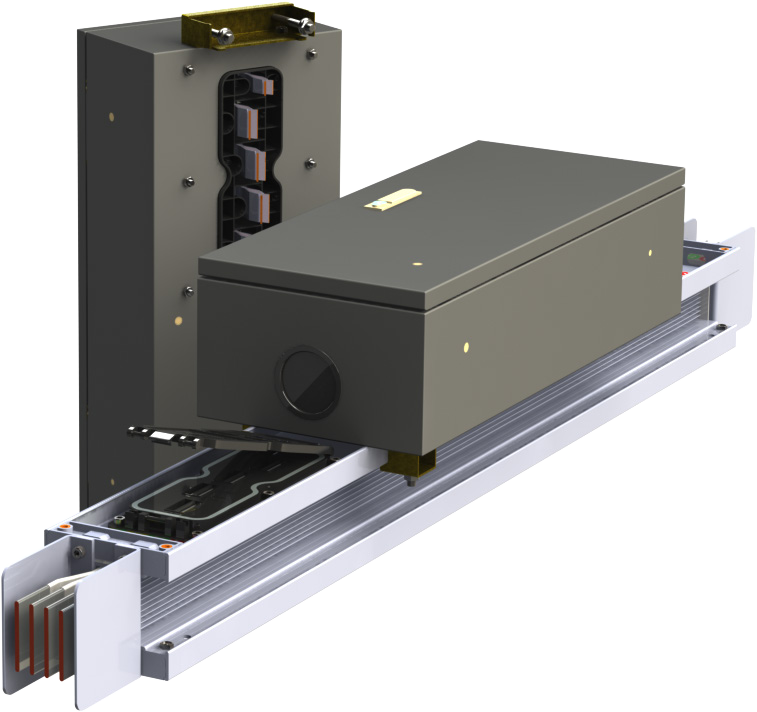

3.5 Reliable tapping unit

The sub interface of jzcb-t system adopts intensive design, with good heat dissipation and low impedance. The general bus plug-in box, socket, pin and box are equipped with guidance and error prevention functions, which can effectively prevent phase dislocation, dislocation and poor contact.

When the broadcasting and receiving box is installed, it is grounded first and then connected to the phase. When it is pulled out, it is separated from the phase first and then from the ground. Fully ensure the operation safety of construction personnel

Each part of the tapping unit is equipped with waterproof adhesive strips, with a protection grade of up to 1p54

3.6 Mounting bracket and accessories

When the bus duct is installed vertically, the system is equipped with special process spring support, which can effectively eliminate the additional stress caused by thermal expansion and cold contraction of the system and building settlement.

When the bus duct is installed horizontally, the system is equipped with adjustable horizontal hanger, triangular support and card code. After the bus duct is installed and leveled, it is fixed with card code to make the installation more flexible and stable. When the bus duct is installed through the wall or floor, the system is equipped with through wall sheath, so that the bus duct will not be polluted when the wall and floor are blocked, and the maintenance and management in the future will be more convenient.

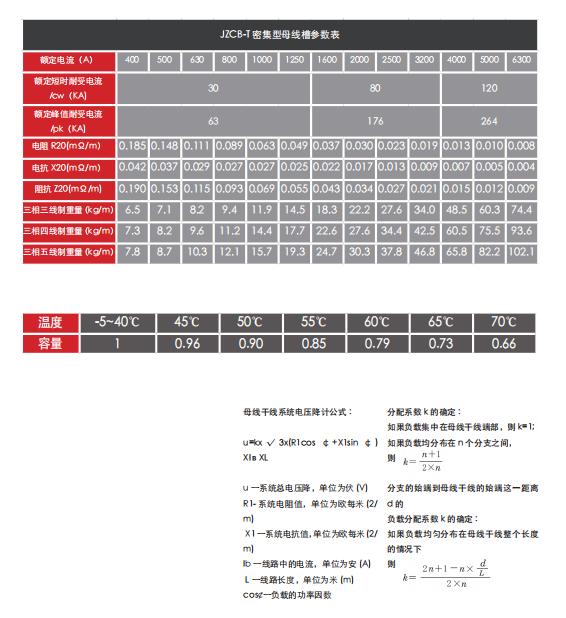

4. Technical reference

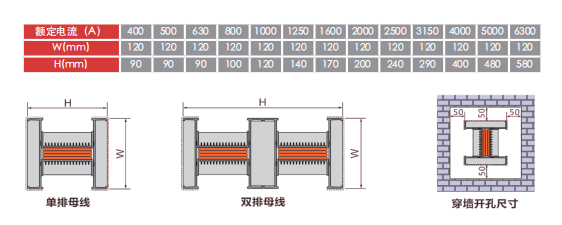

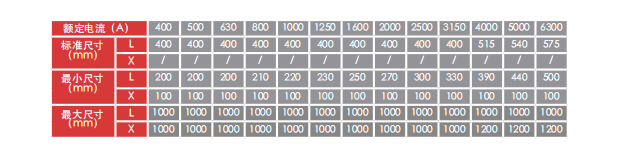

5. Product size

Length of bus duct (L) Note: the length (L) of all products in this manual refers to the distance from the center of the joint to the center of the joint / elbow.

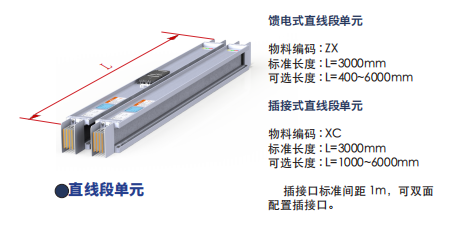

5.1 Linear segment element

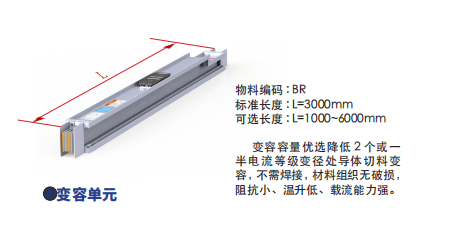

5.2 Varactor unit

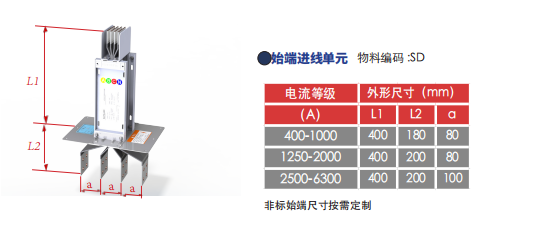

5.3 Initial incoming unit

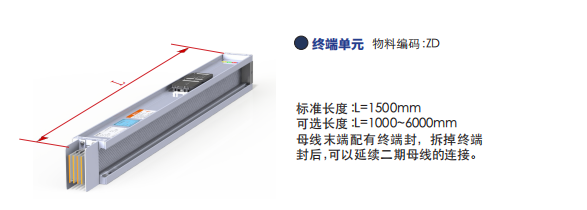

5.4 Terminal unit

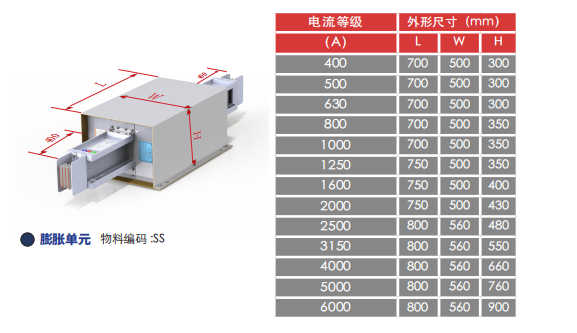

5.5 Expansion unit

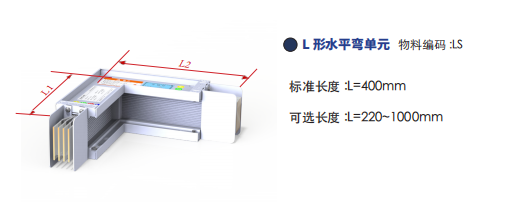

5.6 L-shaped horizontal bending element

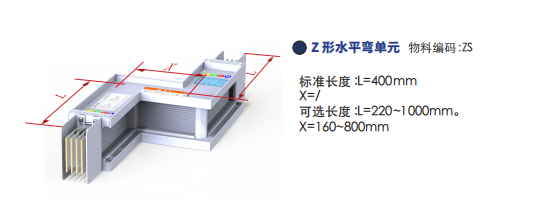

5.7 Z-type horizontal bending element

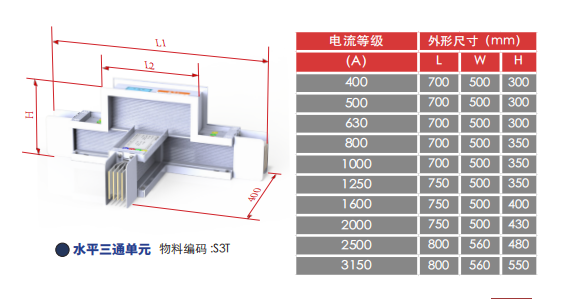

5.8 Horizontal tee unit

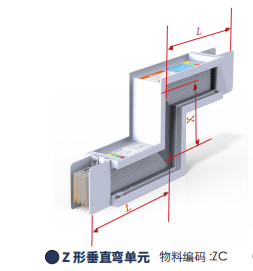

5.9 Z-shaped vertical bending element

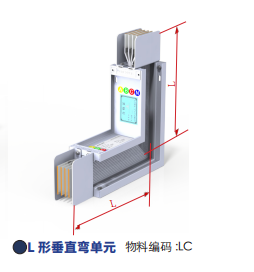

5.10 L-shaped vertical bending element

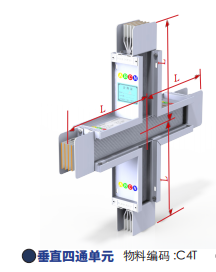

5.11 Vertical cross unit

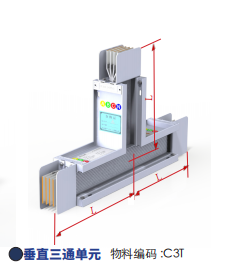

5.12 Vertical tee unit

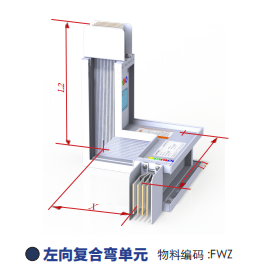

5.13 Left composite bending element

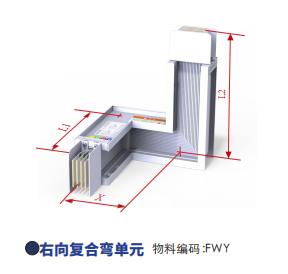

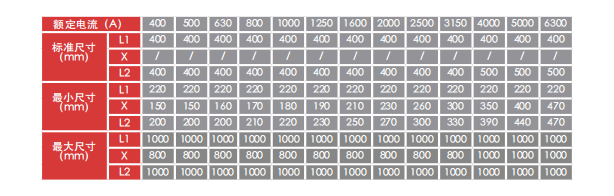

5.14 Right composite bending element

5.15 Plug boxes and other bending units

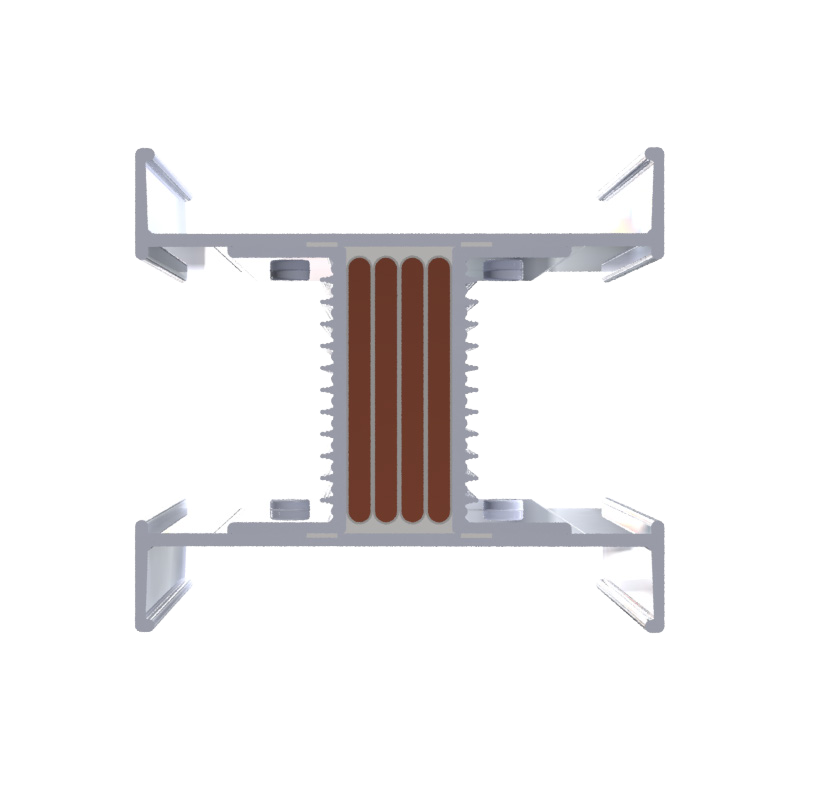

6. Raw material

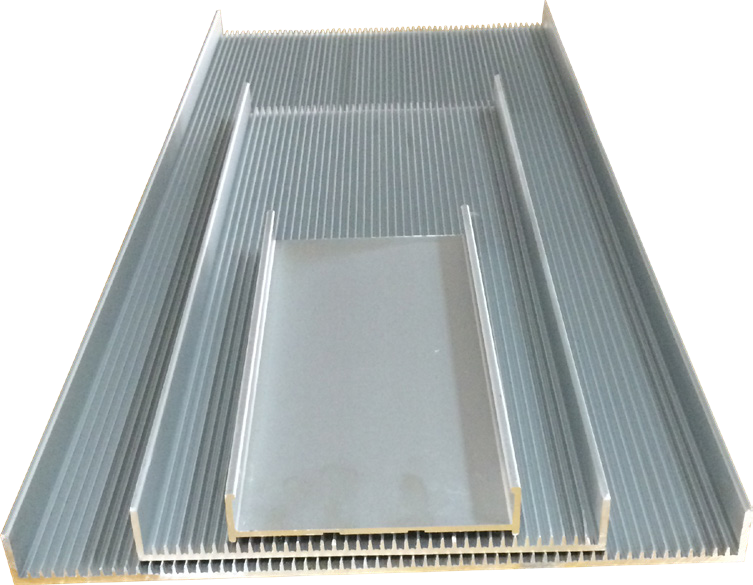

6.1 Aluminum magnesium alloy shell

The shell adopts 6063-T5 aluminum magnesium alloy profile, with less eddy current hysteresis and high mechanical strength. And the side plate is provided with heat sink, which makes the system heat faster, less impedance, lower temperature rise and higher strength. The surface is sand blasted, with strong corrosion resistance and good grounding effect. High safety factor.

6.2 High strength insulation assembly

The interphase insulation adopts American DuPont polyester film, double-layer coating, and the withstand voltage exceeds 20kV. The long term heat resistance index RTI is greater than 130 degrees, the elongation at break is more than 150%, and the anti-aging ability is very strong.

6.3 High conductivity copper bar

The conductor adopts 1# electrolytic copper with copper content of 299.95% and resistivity < 0.017772 · mm2 / m. The full length of the conductor is tinned or silver plated, which can effectively prevent surface oxidation, reduce contact resistance and reduce temperature rise.

6.4 High strength insulation assembly

The bus duct plug-in box, connector insulation partition and other insulation components are made of high-quality electrical insulation material (BMC). The security and stability of the system are greatly improved.

7 Product number